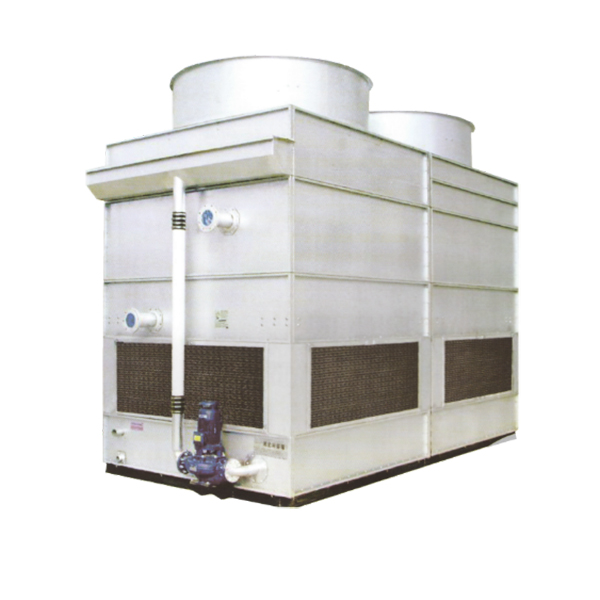

Closed Loop Cooling Tower – Counter Flow

■ Continuous Coil with no seam welding

■ SS 304 coils with Pickling & Passivation

■ Direct Drive Fan saving Energy

■ Electronic De-scalar to reduce Blow down cycle

■ Patented Clog free nozzle

•Material of Construction: Panels and Coil available in Galvanized, SS 304, SS 316, SS 316L.

•Removable Panels (optional): To easily access the Coil and Internal components for cleaning.

•Circulating Pump: Siemens /WEG Motor, Steady running, low noise, Large Capacity but low power.

Principle of Operation: The cooling water is pumped to the spray nozzles above the condensing coil and distributed evenly on the outer surface of the condensing coil, forming a very thin water film. Axial fan induces air from the sides. It enhances air flow forming a negative pressure inside the machine, promoting lower evaporation temperature and water film evaporation, thereby increasing the heat dissipation from the coil.

The water is evaporated which removes the heat.

The high-temperature water flows down from the coil, and comes in contact with fresh air. This lowers the water temperature before it gets collected in the basin below.

| •Chemical | •Tyre |

| •Steel Plant | •Polyfilm |

| •Automobile | •Pharmaceutical |

| •Mining | •Power Plant |